You Can Always Talk to a Kirsh

Kirsh Foundry’s roots date back to the late 1930s. Though many aspects of our business have changed over nearly a century, two things remain constant: our quality and our reputation. The fact that most of our business comes referrals speaks volumes about our work.

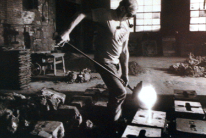

The place where we work reflects that dedication to consistency and excellence. When someone visits the foundry, we often hear amazement. Kirsh is not your ordinary foundry – it is incredibly clean. It is spotless because it reflects the pride our team members have in their work and it makes for a safe place to do that work.

While the essential element of what we do – shaping iron – hasn’t changed much over the last century, we innovated in how we do it. We invested in equipment that allows us to make more castings. We innovated our processes to be safer and more efficient. We offered our team members careers instead of jobs.

So, we’re still thriving in Beaver Dam, Wisconsin, where the best team members are making the best castings for the best customers. Join us.